304 stainless steel v cone tumble bender is made of polished 304 stainless steel, which is clean and hygienic as a whole, not easy to rust, corrosion resistance, high temperature resistance, good sealing, simple operation, suitable for food, medicine and other industries with hygiene requirements, commonly used in powder , Mixing of granular materials. 304 stainless steel v sone tumble vlender produces 5.6L each.

Material: 304 stainless steel

Volume: 14L

Output: 5.6L/time

Stirring speed: 45rpm/min

Mixing time: 6-8min

Power: 0.37KW

Dimensions: 780×350×780mm

Weight: 100kg

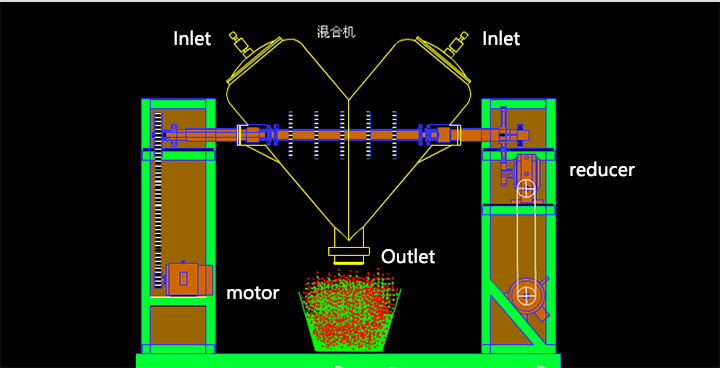

304 Stainless Steel V Cone Tumble Blender utilizes that the lengths of the two cylinders of the mixer are not equal to form asymmetry. When the mixer rotates, the material is decomposed to combination, and from combination to decomposition. Due to the different planes of the material, there is also a lateral force, which pushes the material to communicate laterally. . About 25% of the material flows from one barrel to the other with the lateral force per rotation, so that the materials are mixed laterally and radially, and the decomposition and combination are carried out with each other, so that the materials can achieve a uniform mixing effect.

1. High mixing uniformity: The structure of two cylinders with different lengths is adopted, and there is a time difference in the material flow in the cylinder, so it has extremely high mixing efficiency and excellent mixing uniformity.

2. No residue, no cross contamination, no dead angle between the inside of the cylinder and the contact part of the material, the mixing process is mild, no segregation occurs, the material is discharged completely, there is no residue, and no cross contamination occurs.

3. There is no mechanical extrusion and strong wear, and the material particles can be kept intact. The inside and outside of the barrel are polished, and both are designed to have a smooth transition without dead ends, which can avoid cross-contamination of materials. The discharge port is equipped with a butterfly valve, which is convenient for feeding.

4. Made of 304 stainless steel, corrosion resistance, long life, simple operation and convenient maintenance.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Paddle mixer is mainly used for all kinds of dry-mixed mortar and high-grade putty powder that...

MEKA offers an extensive range of high-performance concrete mixers – Single Shaft, Twin Shaft...

Ribbon mixers are used for consistent, uniform batch or continuous mixing of powders and granu...

China,Yanjin county forest park gate to the west 1000 meters north road.