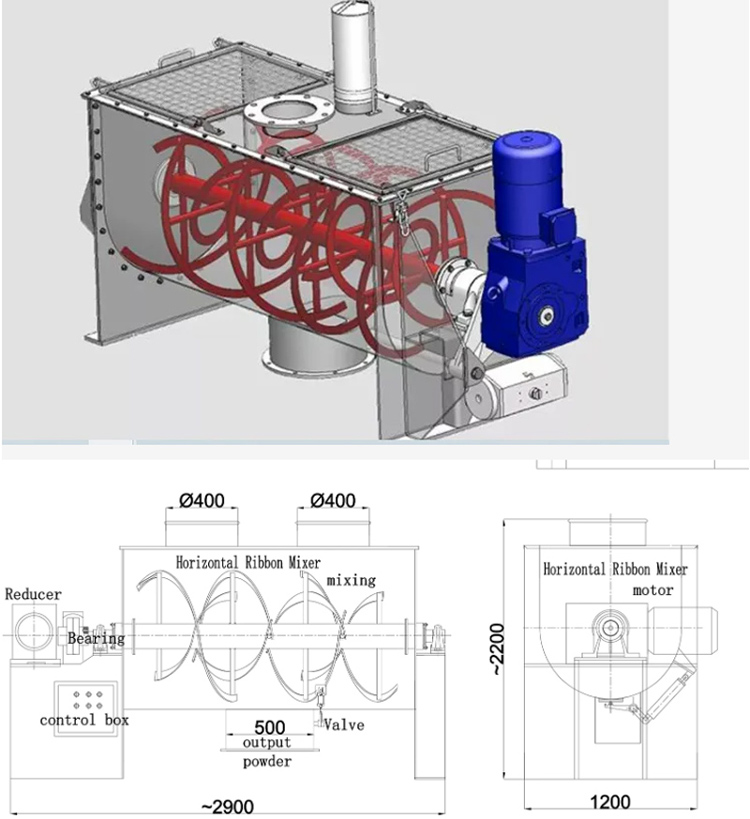

Mixing is a crucial step in the powder coating manufacturing process. Horizontal ribbon blender for making powder coatings is an efficient and uniform horizontal mixer equipment that uses a horizontally rotating ribbon for mixing, providing an ideal solution for powder coating manufacturers. It can efficiently and uniformly mix various raw material powders to ensure the consistency of paint color and texture, and improve product quality and market competitiveness.

The working principle of horizontal ribbon blender for making powder coatings is simple and efficient. When the equipment is started, the double-spiral belt begins to rotate horizontally, shearing, turning and cross-mixing the powder raw materials. The movement of the spiral belt causes the material to continuously reciprocate in the container, thereby achieving full mixing of the material. Through reasonable ribbon design and movement mode, the mixing time is greatly shortened and production efficiency is improved.

First of all, the horizontal ribbon mixer can achieve efficient mixing. The shearing, turning and cross-mixing effects of the double-spiral belt make the materials fully contact and mix, improve the mixing efficiency, and save time and energy costs.

Secondly, the equipment can achieve uniform mixing, ensuring uniform particle size and proportion of various raw materials in the paint, and improving product quality stability.

In addition, the horizontal ribbon blender for making powder coatings also has the characteristics of simple structure, easy operation, convenient cleaning and maintenance, etc., which reduces production costs and labor investment.

Pigment Mixing: It can be used to mix pigment powders of different colors to ensure the uniformity and consistency of the pigment. It can effectively shear, flip and cross-mix pigment particles, so that pigments of different colors can be fully mixed to obtain a uniform color.

Resin Mixing: Resin is one of the important ingredients in powder coating manufacturing. Horizontal ribbon blender for making powder coatings can be used to mix resin powder with other additives to ensure uniform dispersion and dissolution of the resin. It can effectively mix resin particles with other powders to improve the solubility and reactivity of the resin.

Additive mixing: Various functional additives are often added to powder coatings, such as antioxidants, preservatives, leveling agents, etc. Horizontal ribbon blender for making powder coatings can be used to mix these additives with pigments and resins, ensuring even dispersion and effective action of the additives. It can fully mix the additive powder with other ingredients to improve the dispersion and stability of the additive.

Filler Mix: Some powder coatings require the addition of fillers to increase the hardness, abrasion resistance and filling properties of the coating. Horizontal ribbon blender for making powder coatings can be used to mix filler powder with other ingredients to ensure even dispersion and effective filling of fillers. It can fully mix filler particles with other powders to improve filler dispersion and filling effect.

The application of Horizontal ribbon blender for making powder coatings not only improves the quality of powder coatings, but also improves production efficiency and corporate competitiveness. By optimizing the mixing process, manufacturers can reduce costs and improve product consistency and stability. With the continuous advancement of technology, the design and performance of horizontal ribbon blender for making powder coatings are also constantly innovating and improving. Some advanced equipment are equipped with automated control systems to achieve precise control and monitoring of the mixing process, further improving the accuracy and stability of mixing.

In short, horizontal ribbon blender for making powder coatings, as a powerful tool for making powder coatings, has the advantages of efficient mixing, uniform mixing, and easy operation. It not only improves product quality and production efficiency, but also brings more economic benefits to manufacturers. Whether it is the mixing of pigments, resins or additives, horizontal ribbon mixers provide reliable support and assistance to powder coating manufacturers. When you choose horizontal ribbon blender for making powder coatings, you will have an efficient and reliable mixing equipment to help you create higher quality powder coating products.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Paddle mixer is mainly used for all kinds of dry-mixed mortar and high-grade putty powder that...

MEKA offers an extensive range of high-performance concrete mixers – Single Shaft, Twin Shaft...

Ribbon mixers are used for consistent, uniform batch or continuous mixing of powders and granu...

China,Yanjin county forest park gate to the west 1000 meters north road.