4000L Ribbon Mixer Horizontal Ribbon Mixer Equipment Rare Earth Ribbon Dryer

Ribbon mixer is also called horizontal ribbon mixer. It consists of a U-shaped horizontal groove and a special ribbon agitator. The spiral belt blade has an inner and outer double structure. The material is collected from the outer spiral to the center, and the inner spiral conveys the material from the center to both sides. , to form convection mixing, the surface of the inner cylinder is polished, equipped with a central shaft and double S-shaped paddles, the mixing process is fast and uniform, and each batch can be completed within 5-10 minutes.

Horizontal ribbon mixer is suitable for mixing viscous or viscous powder and adding liquid and paste powder with good mixing effect. The cylinder head can be made into a fully open type, so that the equipment can replace cleaning products.

Ribbon mixer is generally used for the mixing of viscous or cohesive powders and granules, as well as the mixing of liquid and paste materials added to the powders and granules. It is suitable for occasions with large output and infrequent replacement of varieties, and is used in chemical industry, medicine, fertilizer and paint. , pigment, feed, aquaculture, medicine, food, and other industries solid-solid (that is, powder and powder) mixing, solid-liquid (that is, powder and liquid) mixing, liquid-liquid (that is, liquid and Liquid) mixing, powder and slurry material mixing. The product has the characteristics of short mixing time, high production capacity, uniform mixing, low cost of use, high efficiency, and convenient and quick unloading. The machine has wide adaptability to mixtures, and will not produce layering and segregation for the mixing of heat-sensitive materials, and will not crush and grind granular materials. The mixing of flake materials also has good adaptability.

Capacity: 10~20,000L per batch

Mixing time: 5~15 minutes

The working principle of the ribbon mixer is that the materials of various components are calculated according to the formula ratio and then enter the mixer, and the materials are mixed under the impetus of the ribbon spiral blade. The outer spiral belt pushes the material from one end to the other, and the inner spiral belt makes the material move in the opposite direction. Roll out and in. In the process of convection, the two streams of material penetrate each other and become mixed, and they are mixed again during the tumbling process on both sides. This is repeated many times. Finally, the uniformly mixed waste is discharged from the discharge door through the discharge control mechanism. out.

1. The inner and outer two-layer spiral belt has a unique structure, runs smoothly, and has a variety of agitator structures, which is a multi-functional mixing device with a wide range of uses.

2. The mixing speed is fast, the mixing uniformity is high, especially the viscosity, and the scraper can be installed on the spiral belt, which is more suitable for thick and paste mixing.

3. Under the mixing requirements of different materials (special materials must be mixed and cleaned every time), different spiral belt structures are used, and the jacket type can be heated and dried.

4. The capacity of continuous mixing per hour ranges from 50L to 20000L.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-600 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

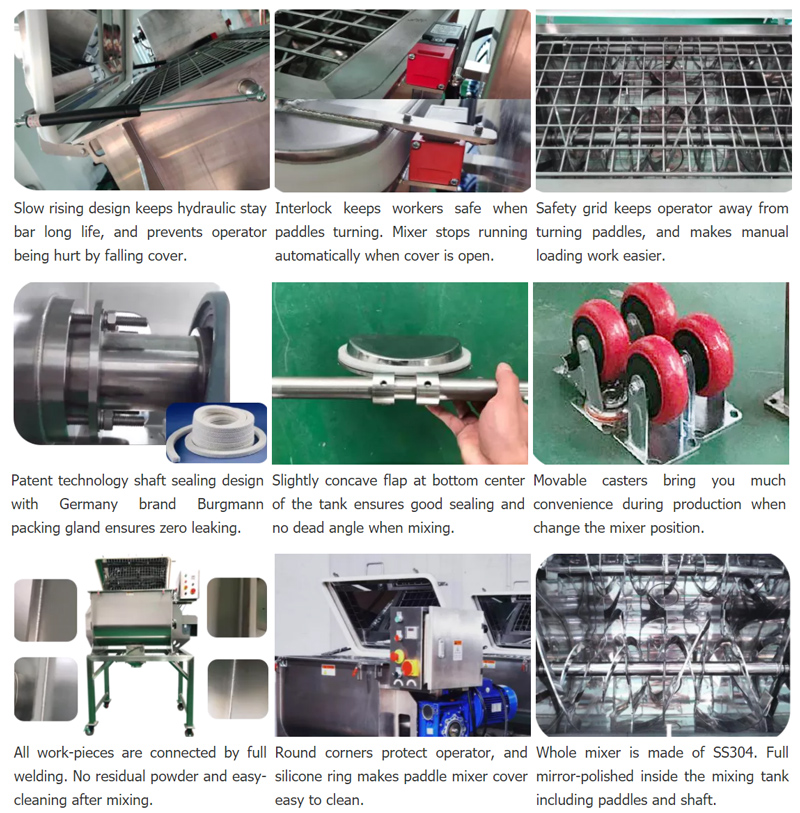

1. Materials

Materials can be carbon steel, manganese steel, ss304, 316L and 321; in addition, different materials can be used in combination. Stainless steel surface treatment including sandblasting, wire drawing, polishing, mirror polishing, can be used for different parts of the mixer

2. Motor

Motor options: general motor, explosion-proof motor, variable frequency motor, high-efficiency and energy-saving motor. Commonly used reducers: R series, K series, F series gearboxes; cycloid reducer, universal gear reducer, planetary gear reducer. Common motor-gearbox connection methods: direct connection, pulley connection, fluid coupling connection.

3. Feeding port

Various air inlets on the top cover of the bucket can be designed according to different situations and can be used as manholes, sweeping doors, feeding holes, exhaust holes and dust collecting holes. The top cover can be designed as a fully open cover for easy cleaning.

4. Discharge port

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

5.Mixing unit

Different main shaft agitators can be equipped according to the properties of raw materials.

The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

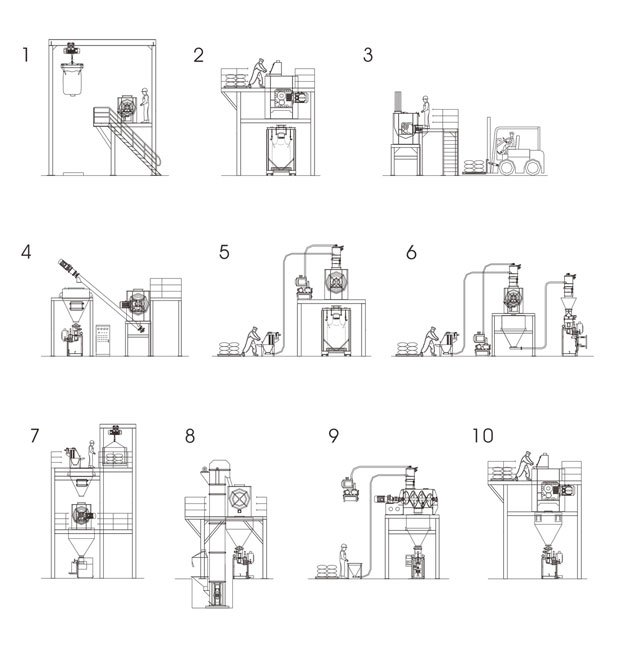

Configuration 1: Use ton bags of raw materials, hoist it on the road, and directly feed the material in combination with the dust collector.

Configuration 2: Set up a multi-layer platform, manually unpack and feed materials, and use a ton belt packaging machine after mixing and discharging.

Configuration 3: The easiest to use mixing equipment, direct feeding and direct discharging, and forklift loading and unloading.

Configuration 4: Using a manual feeding platform, after the materials are mixed, they are spirally lifted into the finished product warehouse, and then connected to the packaging equipment.

Configuration 5: The vacuum feeding method is adopted, the ground is fed, and the ton belt packaging machine is used after mixing and discharging.

Configuration 6: Multi-stage vacuum feeding and conveying, mixed and stored, and then packaged.

Configuration 7: Multi-layer operating table design, freight elevator feeding, feeding, warehousing, mixing, storage, packaging, integrated tower structure.

Configuration 8: The vacuum feeding method is adopted, the ground is fed, and the ton belt packaging machine is used after mixing and discharging.

Configuration 9: Vacuum feeding machine feeding, mixing, warehousing, packaging, and the upper and lower integrated structure.

Configuration 10: Manual feeding, mixing, warehousing, packaging, and the upper and lower integrated structure.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

What is Horizontal Ribbon Mixer? Horizontal ribbon mixer is a kind of equipment used for mixing, st...

Stainless steel ribbon mixer is made of 304 or 316L stainless steel. It is used for mixing powder mat...

Fertilizer ribbon mixer is mainly used to stir various fertilizers and organic fertilizers to improve...

China,Yanjin county forest park gate to the west 1000 meters north road.