Analyze the physical quantity of the quality of the material, obtained by probability theory, and the mixing uniformity is determined by the type of mixing equipment.

Fertilizer ribbon mixer is suitable for mixing and stirring powder or granular fertilizer materials. It has the advantages of fast mixing, uniform mixture, convenient operation and easy cleaning. In addition, fertilizer raw materials are generally corrosive, so fertilizer ribbon mixer is made of 304 stainless steel. The mixer of this material is resistant to acid and alkali and will not react chemically with the raw materials, and can be specially used for mixing various fertilizers, organic fertilizers and chemical raw materials.

To produce good organic fertilizer, the choice of fertilizer ribbon mixer is the key. Since the organic fertilizer is relatively viscous, water-based additives need to be added, resulting in a heavier proportion of the material, and the general mixer cannot provide organic fertilizer production. Devices need to be manufactured according to material properties.

Mixed fertilizer: Particles made by mixing different types of fertilizer particles in a certain proportion, which can provide a variety of nutrients to crops. Common mixed fertilizers include compound fertilizers, compound fertilizers, etc.

Slow-controlled release fertilizer: This kind of granules is made of a mixture of different types of fertilizer granules. Through special coating or wrapping technology, nutrients are slowly released over a period of time to meet the needs of crops.

Multi-element fertilizer: The mixer can mix different types of fertilizer particles together to form granular fertilizer containing multiple elements, so that crops can obtain a supply of multiple nutrients.

Customized fertilizer: The mixer can also mix different types of fertilizer particles in a certain proportion according to the needs of specific crops and soil characteristics to form customized fertilizer particles suitable for specific crops and soil.

It’s important to note that the specific granule types and ratios mixed will vary based on different fertilizer formulations, crop needs and soil conditions. The proportion of mixed fertilizer needs to be adjusted according to specific conditions to meet the nutrient needs of crops and soil improvement requirements.

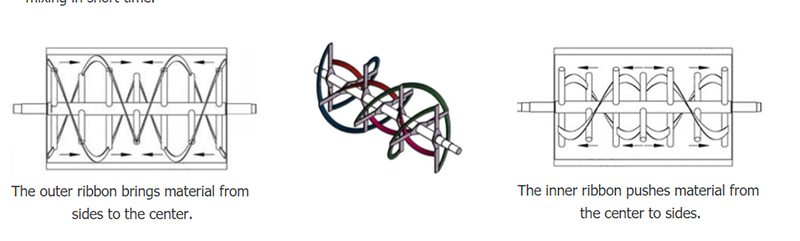

Fertilizer ribbon mixer is to put the raw materials into the mixer according to the proportion through the ribbon, start the mixer, the raw materials are stirred and mixed under the push of the spiral blades, the outer ribbon pushes the raw materials to the other side, and the inner ribbon pushes the raw materials to the opposite direction. Pushing, so repeatedly, the raw materials are stirred and mixed evenly under the action of convection. During this process, water, liquid, and spray can be added. Finally, the raw material is discharged through the control valve at the bottom.

1. The fertilizer raw materials are corrosive, so the mixer is generally made of 304 stainless steel, which is not easy to corrode.

2. The positive and negative rotating ribbons are installed on a unified horizontal axis to form a low-power mixing environment. The ribbon-shaped blades are generally made into two layers or three layers, which speeds up the mixing speed and increases the mixing average.

3. On the basis of the original, the motor power, stirring shaft and mixing blade of the ribbon mixer are enlarged to meet the mixing and stirring of fertilizers with high viscosity.

4. The design of the discharge port adopts the butterfly valve to open the door to discharge the material, so that the viscous fertilizer is easily discharged from the mixer, the discharge is fast, and the output can reach 4-8 tons/hour.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

|

One-time mixing (kg) |

100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-600 |

|

Mixing time (min) |

8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

|

Mixing speed (r/min) |

60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

|

Motor power (kw) |

3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

|

Weight (kg) |

500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Ribbon mixers are used for consistent, uniform batch or continuous mixing of powders and granules, with mixing volumes ra ......

Feed ribbon mixer is used in feed mill to mix various grain powders to make nutritious feed pellets, especially suitable ...

Stainless steel ribbon mixer is made of 304 or 316L stainless steel. It is used for mixing powder materials such as cosme ...

China,Yanjin county forest park gate to the west 1000 meters north road.