Ribbon blender is a special equipment for mixing powder, small particles, liquid and other materials, so how should we select a ribbon blender?

1. Mixing time and yield

The processing time of each batch of materials in Ribbon blender is about 10 minutes, plus the time of discharging and feeding materials, the processing time of each batch of materials can be calculated as 15 minutes, and 4 batches of materials can be processed continuously in one hour. If you choose a ribbon blender that processes 100kg of material per batch, you can process 400kg in 1 hour. Users can choose the ribbon blender model according to their production needs.

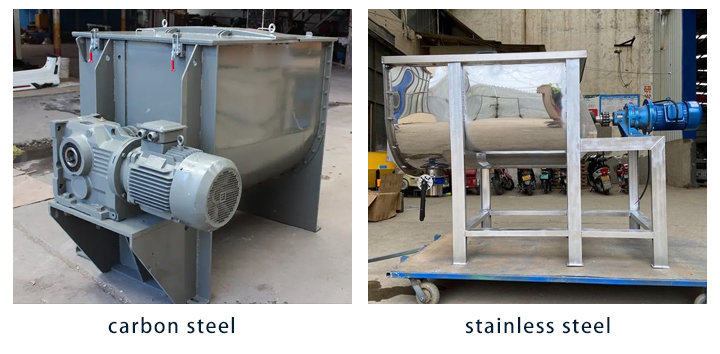

2. Material

The materials of the Ribbon blender are carbon steel and stainless steel. According to the properties of the materials, the material selected is different: the carbon steel ribbon blender is suitable for conveying common materials, such as cement powder, dry powder, etc.; the stainless steel ribbon blender has corrosion resistance, high temperature resistance, Clean and hygienic, not easy to rust, suitable for industries with strict hygiene requirements such as food and medicine, you can choose the material according to the material.

3. Ribbon type

Ribbon blender chooses different ribbons according to the characteristics of the material to be stirred:

Shearing: The material is thick and viscous, and a shearing agitator can be selected. Fragile materials: If the material breaks easily during mixing, use a mixer with a lower mixing speed, such as a paddle mixer.

Single or double ribbons: The mixing time of the double ribbons is short. If you want to mix quickly and the mixing time is short, the double-ribbon belt, of course, requires a large motor power.

4. Discharging method

When choosing a ribbon blender, you should communicate with the manufacturer to choose the valve form suitable for your own process. It is not recommended to choose the discharge form of the side port. Because when the ribbon blender completes the stirring and mixing within the specified time, it can ensure the uniformity of the material by releasing it once in the shortest time; The best uniformity has been reached, and excessive stirring will cause the material to segregate and destroy the uniformity.

In short, choosing a suitable ribbon blender will significantly improve the quality of the mixture, and can also greatly reduce material costs and increase production profits.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Paddle mixer is mainly used for all kinds of dry-mixed mortar and high-grade putty powder that...

MEKA offers an extensive range of high-performance concrete mixers – Single Shaft, Twin Shaft...

Ribbon mixers are used for consistent, uniform batch or continuous mixing of powders and granu...

China,Yanjin county forest park gate to the west 1000 meters north road.