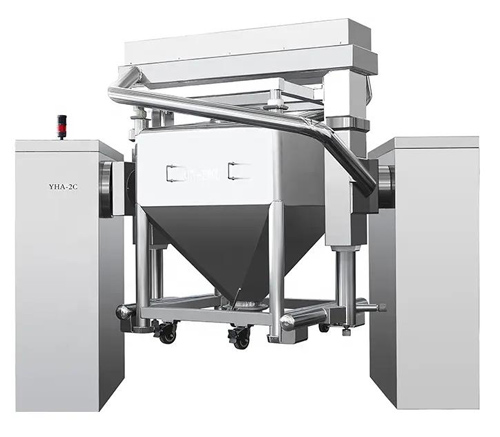

Automatic lifting hopper mixer is a kind of equipment commonly used in pharmaceutical, chemical, food, metallurgy and other industries to mix materials with different components evenly. The structure of the automatic lifting hopper mixer is composed of a hopper, a lifting device, a mixing device and a control system.

1. Hopper: Usually a large-capacity container used to store raw materials and mixed materials.

2. Lifting device: It is usually composed of a motor, a belt or chain, a lifting mechanism, etc., and is used to lift the hopper to a suitable position.

3. Mixing device: usually composed of mixing tank, agitator and stirring motor, etc., used to mix raw materials.

4. Control system: used to control the entire mixing process, including controlling the lifting of the hopper, controlling the stirring of the mixing tank, etc.

The main parts of the automatic lifting hopper mixer are the hopper, lifting mechanism, mixing mechanism and control system. There is a lifting mechanism above the hopper, which can lift the material to a certain height, and then the material enters the mixing mechanism through the action of gravity. The mixing mechanism generally consists of a stirring device and a mixing chamber, and the stirring device can uniformly mix materials. The control system can adjust the lifting speed, stirring speed and mixing time according to the needs to realize automatic operation.

1. The automatic lifting hopper mixer has the characteristics of simple structure, convenient operation and convenient maintenance, which can improve work efficiency.

2. The equipment has a good mixing effect, which can evenly mix materials of various shapes, particle sizes and specific gravity to improve the quality of the product.

3. The stirring device adopts a special design, which can improve the stirring effect and reduce energy consumption.

4. The control system has an automatic function, and parameters can be adjusted according to production needs to achieve precise mixing process control.

1. Pharmaceutical industry: It is used to prepare pharmaceutical tablets, granules, suspensions and other drugs. It can fully mix various pharmaceutical ingredients and improve the uniformity of the drug.

2. Chemical industry: used for mixing powder and granular materials, and can be used to prepare various chemical products, such as dyes, ceramic raw materials, etc.

3. Food industry: It is used in the preparation of food additives, condiments, biscuits and other foods, which can improve the uniformity and quality of products.

4. Metallurgical industry: It is used for mixing granular materials such as ore and fly ash, which can improve the uniformity of ore, thereby improving smelting efficiency.

The automatic lifting hopper mixer is a commonly used mixing equipment, which has the advantages of simple structure, convenient operation and good mixing effect, and is widely used in pharmaceutical, chemical, food, metallurgy and other industries. In different application scenarios, the mixing requirements of different materials can be achieved by adjusting parameters, improving production efficiency and quality.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

China,Yanjin county forest park gate to the west 1000 meters north road.