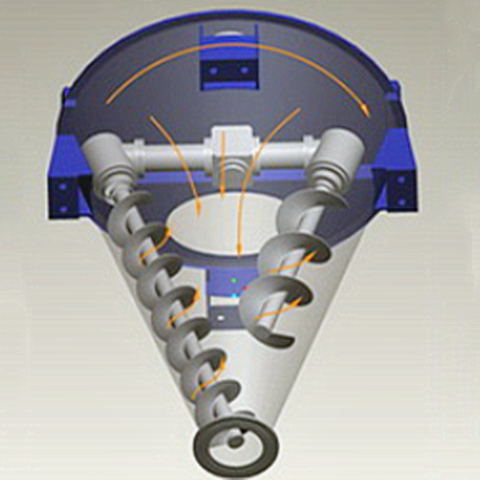

Conical twin screw mixer is a kind of equipment commonly used for material mixing, which has the characteristics of good mixing effect, easy operation and low power consumption. The working principle, types and uses of the conical twin-screw mixer will be introduced below.

The working principle of the conical twin screw mixer is to use two conical rotating spirals to drive the material to continuously turn and mix. Under the action of the conical spiral, the materials are continuously turned up and down, so that the materials are mixed in all directions during the whole mixing process to achieve the purpose of uniform mixing. The special structure of the conical double helix can better ensure that the materials are fully mixed and avoid the generation of dead ends.

According to different needs, the conical twin screw mixer can be divided into the following types:

1. Vertical conical twin screw mixer: suitable for mixing powdery and granular materials. It has the characteristics of simple and compact structure, large capacity and short mixing time.

2. Horizontal conical twin screw mixer: suitable for mixing viscous materials. Its specially designed double helix structure allows viscous materials to be fully mixed, and the operation is stable and reliable.

3. Stainless steel conical twin screw mixer: suitable for industries requiring high hygienic standards such as food and medicine. Its material is stainless steel, which is easy to clean and maintain, and meets the hygienic requirements of related industries.

1. Efficient mixing: The conical twin screw mixer adopts a symmetrical double-helix structure, which can mix materials quickly and evenly. The spiral movement makes the materials fully turned and folded during the mixing process, so that the components can be mixed better and the mixing effect can be improved.

2. Strong adaptability: the mixer is suitable for mixing various materials, including materials in different forms such as powder, granular, and fibrous. And the rotation speed and mixing time of the screw can be adjusted to meet the mixing requirements of different materials.

3. Easy to operate: The conical twin screw mixer has simple structure and is easy to operate. Simply put the materials into the mixer and start the machine to complete the mixing process without too much manual operation.

4. Easy to clean: The mixer is made of all stainless steel structure, the interior is smooth, it is not easy to accumulate materials, and it is easy to clean and maintain.

5. Low energy consumption: The conical twin screw mixer consumes less energy during the mixing process, has a high energy utilization rate, and meets the requirements of energy conservation and environmental protection.

1. Chemical industry: used for mixing pigments, dyes, rubber, plastics and other materials.

2. Grain industry: used for mixing grain, feed and other materials.

3. Mining industry: used for mixing coal, ore and other materials.

4. Pharmaceutical industry: used for mixing medicine powder, granules and other materials.

5. Food industry: used for mixing condiments, powdered sugar, protein powder and other materials.

In short, the conical twin screw mixer is a widely used mixing equipment. It drives the material to flip and slide through the rotation of the double helix, so that the material can be fully mixed during the entire mixing process to achieve a uniform mixing effect. Different types of conical twin screw mixers are suitable for different fields and have good application prospects.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

China,Yanjin county forest park gate to the west 1000 meters north road.