The respective flow characteristics, ingredient amount, bulk density, particle size, moisture, etc.

Dry mortar plant mainly mixes dry sand with other additives such as cement and fly ash in a certain proportion, suitable for dry powder mortar, dry mixed mortar, thermal insulation mortar, ready-mixed mortar, admixture, jointing agent, interface agent, putty powder , chemical powder, etc. stirring, mixing, measuring, packaging.

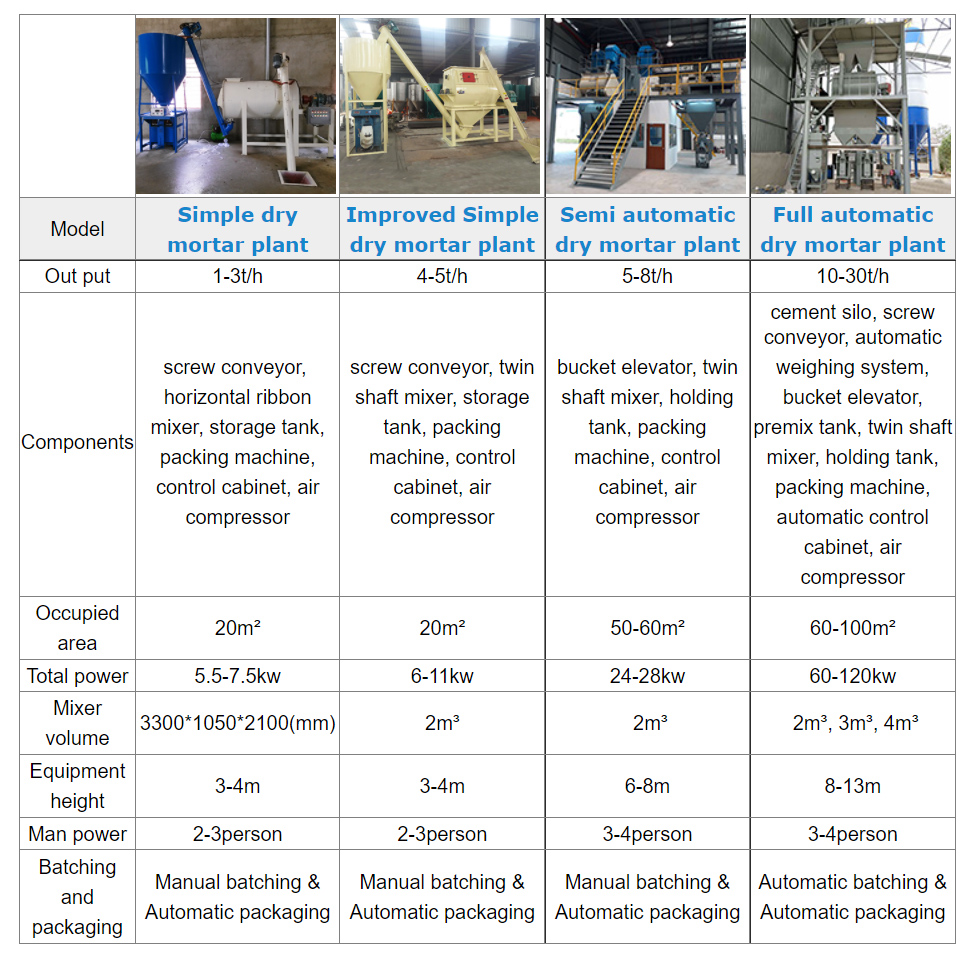

1. Simple Dry Mix Mortar Production Line

On the basis of dry mortar mixer, screw conveyor, finished product hopper, simple dust collector and automatic valve packing machine are added, and three-layer dry mortar paddle mixer is adopted, and the mixing time of each batch is 10-15 minutes, which can be uninterrupted for 24 hours Work. The height of this simple dry powder mortar production line is no more than 4 meters, the floor space is small, and the investment is small. It is a simple and practical production line.

2. Improved Dry Mortar Production Line

The improved dry mortar production line workshop covers an area of 100 square meters, the equipment covers an area of 20 square meters, and the equipment height is 4.2 m. It requires 2-3 people to operate the machine, and a batch of 1000kg.

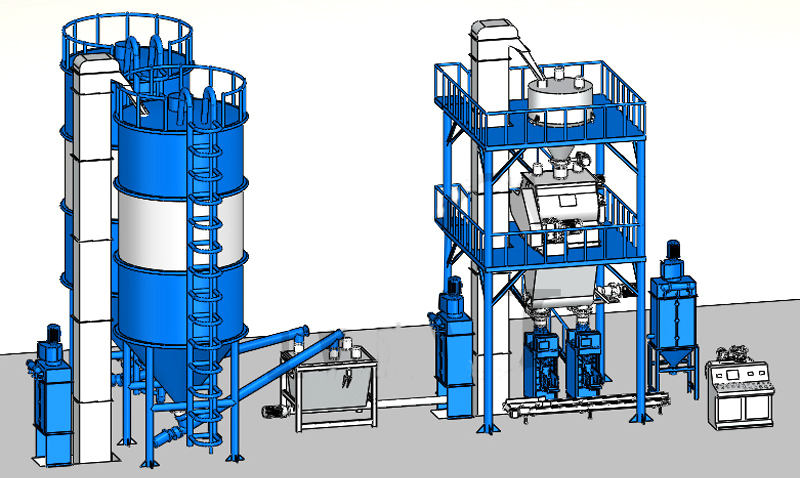

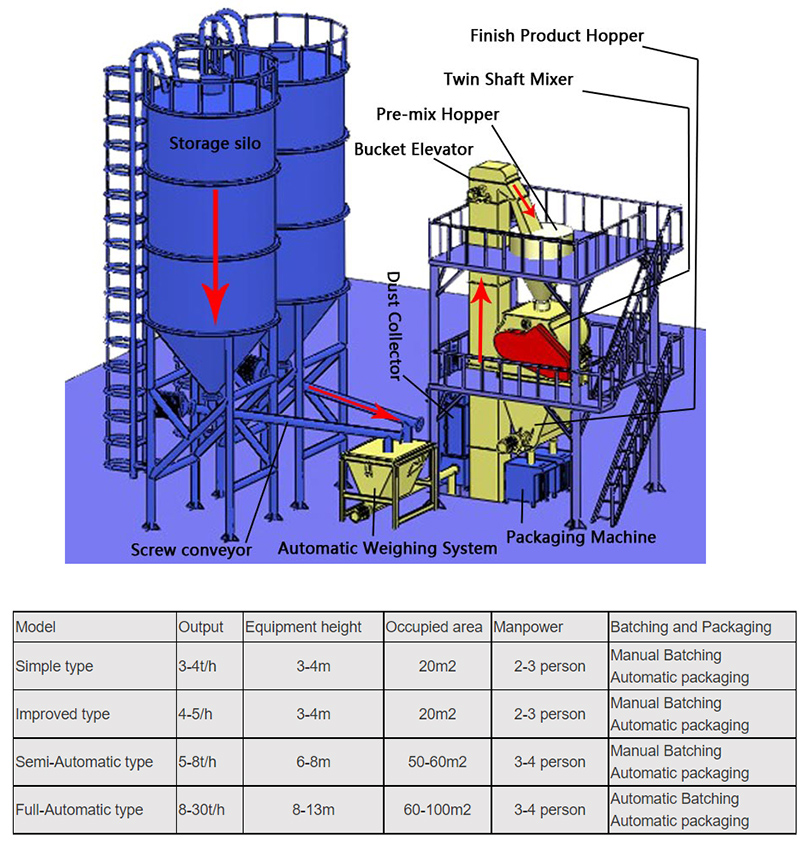

3. 10-30 T/H Dry Mortar Mix Plant

High degree of automation, automatic feeding, automatic mixing, automatic unloading, only one person can complete the operation of the whole set of dry mortar mixing plant, saving manpower and material resources.

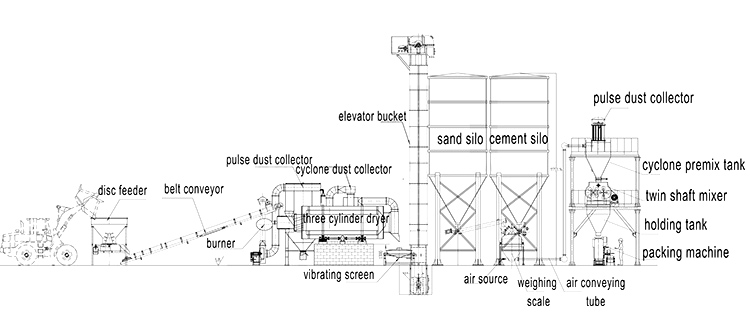

The main mechanical equipment of dry powder mortar equipment are: mixer, batching device, sand drying device, raw material tank, conveying and lifting device, dry powder packaging machine, dust collector, and control system. The mixer is the core part of the dry mortar equipment, which determines the uniformity of the finished product of the dry mortar production line. The requirements of the dry mortar equipment for the mixer are uniform mixing, high efficiency, wear-resistant equipment and fast discharge speed.

1. Feeding hopper: used to feed materials to the bucket elevator.

2. Bucket elevator: used to lift materials to the warehouse to be mixed.

3. Double-shaft gravity-free mixer: used for uniform mixing of materials, and the special flying knife group can disperse cellulose. It adopts the form of double large opening doors, the discharge is fast and uniform, and the stirring time of each batch is 3-5 minutes.

4. Finished product warehouse: used to store the mixed finished materials, and perform secondary stirring and mixing, waiting for sub-packaging. The bottom of the finished product warehouse can be designed to connect an automatic metering packaging machine and a manual discharge valve.

5. Automatic weighing and packaging machine: It is used to sub-pack the finished materials in the finished product warehouse. It can automatically measure the weight and has high accuracy.

6. Pulse dust collector: used to absorb the dust generated in the production process, mainly used for the centralized dust removal of the feeding port and the packaging machine.

7. Control cabinet: used for electrical switch control of this production line. The control system is divided into instrument control and computer control.

1. It has a wide range of applications and can meet the production needs of dry mortar with different performance requirements. Such as: masonry mortar. Plastering mortar. Mortar required for insulation system. Decorative mortar and other dry powder mortar.

2. The mixing speed is fast, the machine occupies a small area, the operation is simple, the production speed is fast, and there is no dust.

3. The configuration is reasonable. The annual output of the production line is about 20,000-30,000 tons of dry powder mortar. Generally, 4-6 raw material tanks are used, including two large tanks for bulk cement and fly ash, and the other small tanks are used to hold light, heavy, Sand and small materials.

4. The to-be-mixed bin is a pneumatic door type, and the materials that need to be mixed can be put into a gravity-free mixer to achieve uninterrupted production of dry powder mortar.

4. Cost-effective, it is a production project for external wall insulation and decorative mortar, not only low investment, high efficiency, but also avoiding equipment idleness and resource waste caused by excessive investment.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Introduction Liter mixer is a kind of equipment used for mixing various materials, widely used in che...

Introduction The food additive mixer is a kind of equipment widely used in the food industry, mainly ...

Introduction Vertical screw mixer is a common powder mixing equipment, widely used in chemical indust...

China,Yanjin county forest park gate to the west 1000 meters north road.