Performance depends on the recipe, the quality of the raw materials, the installed equipment and its settings.

Feed production line is specially designed for the production of pelleted feed for livestock feed pellets such as fish, sheep, cattle, rabbits, horses, chickens, ducks, geese, pigs, etc. This small feed pellet production plant produces feed pellets between 2mm and 8mm in diameter.

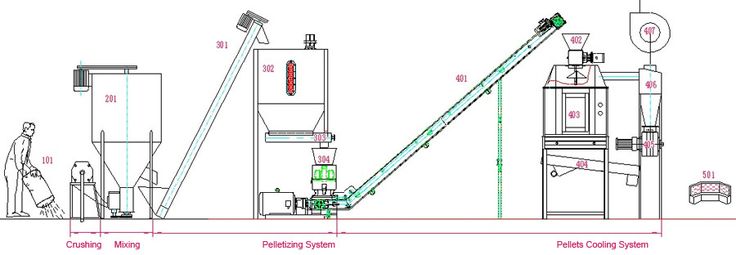

A feed production line contains all the machinery required to produce pellet feed, including all processes of pellet production from crushing, mixing, raw material pelleting, conveying and cooling.

Feed production line application block: small bottom material factory, farm, organic fertilizer factory, we can design a complete pellet production line according to your raw materials and specific requirements.

1. Make poultry feed pellets such as chicken feed pellets, duck feed pellets, etc.

2. The green plants such as domestic waste are processed into pellet feed for poultry feed.

2) Raw materials: Rice husks, straw, cotton stalks, cottonseed husks, weeds, crop straws and other plant wastes, especially low-adhesion and unformed materials.

The moisture content of raw materials should be lower than the national standard of 13%. If not, the ingredients must be dry. The size of the raw material should be less than 5mm, otherwise; the raw material must be crushed with a hammer crusher.

The feed production line is a complete set of equipment specially used to make poultry feed pellets. The production capacity of this poultry feed processing plant varies from 1 ton per hour to 10 tons per hour. Poultry feed processing production line generally includes the following processes: raw material receiving and cleaning process, crushing process, mixing process, pelletizing process, pellet cooling process, (particle crushing process), screening process and packing process

sequence.

Generally speaking, a feed production line process includes the following steps:

1. Pulverize the raw materials or feed materials needed by animals into powder by a pulverizer, such as soybean meal, corn, wheat, vegetables and other materials

2. Then, in the mixer, the pulverized raw material powder is completely mixed for the subsequent granule production process. During this process, the user can add additives such as vitamins, powders, bones and other necessary trace elements

3. Next, the mixed raw materials enter the poultry feed pelletizer through the conveyor. Under high temperature and pressure inside the machine, the loose material is pressed into solid particles of high density, uniform size and shape.

4. The finished pellet feed is then cooled and screened in pellet coolers and screens for later packaging and storage.

5. Finally, by cooling and sieving, the pellets can be stored in bags. The bagged granules are ready for sale in the market.

1. Crushing process: hammer crusher

Hammer mill feed crusher is suitable for grinding raw materials into powder with optimum particle size for best pelletizing effect.

2. Mixing process: feed mixer

The crushed materials are lifted to the high-level silo, and then the materials from different silos are put into the mixer for mixing.

3. Granulation process: flat die granulator

The mixed material needs to be lifted again and sent to the feed granulator for granulation. The production process is the core link of the granulator, and abnormal conditions must be monitored and dealt with in time.

4. Packaging process: packaging machine

The final step in the pellet production process is packaging. The qualified products are packaged for easy packaging and transportation.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Ribbon mixers are used for consistent, uniform batch or continuous mixing of powders and granules, with mixing volumes ra ......

Gravityless twin shaft paddle mixer, also called gravityless mixer, is used to mix powder materials such as dry powder mo ...

China,Yanjin county forest park gate to the west 1000 meters north road.