Pheumatical, electrical and manual discharging metod.

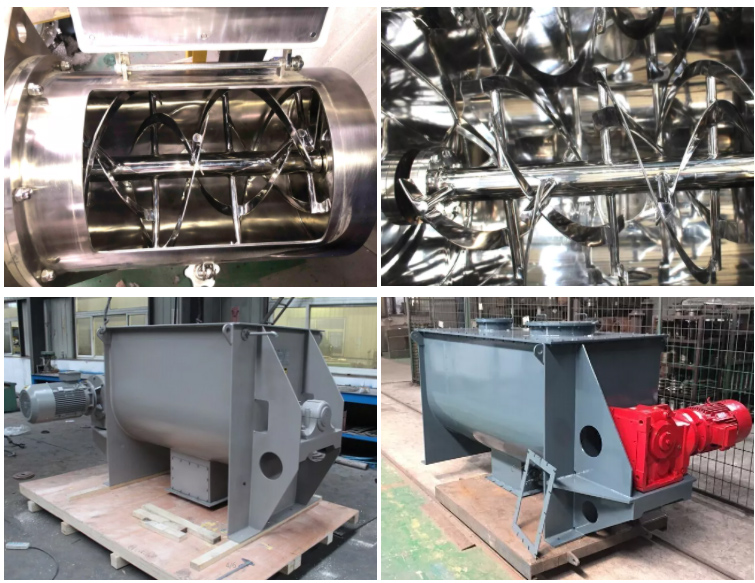

Gravityless mixer is a horizontal body, which is a double-shaft paddle-type forced stirring equipment. It is equipped with a double-shaft multi-blade counter-rotating rotor. The paddles are at a certain angle, and the paddles drive the material to rotate, instantly losing weight. That is, they rotate in opposite directions and fall into each other's area. The materials are infiltrated and mixed back and forth. The central part forms a fluidized weightlessness area and a rotating vortex area, and moves radially along the axis to form an all-round composite cycle and quickly achieve mixing. evenly.

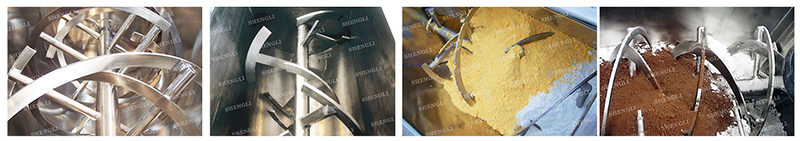

Gravityless mixer can be used for the mixing of powder and powder, powder and mucilage, and is especially suitable for the mixing of viscous materials.

The working principle of the gravityless mixer is that the material in the machine is subjected to the action of two oppositely rotating rotors to perform a consistent movement. On the one hand, the propeller drives the material to rotate counterclockwise along the inner wall of the machine slot, and on the other hand, it drives the material to turn left and right, forming a weightless area where the two rotors overlap. The material is floated in an instant weightless state, which enables the material to be continuously turned in all directions in the machine tank, and sheared staggeredly with each other, so as to achieve the effect of fast, gentle and uniform mixing.

1. It has high mixing uniformity, no dead angle in mixing, and short mixing period.

2. The discharge adopts the bottom full-length door opening structure, which can discharge quickly and has a low residual rate.

3. The discharge sealing is reliable and there is no leakage.

4. The loading capacity has a large variable range, and the machine can be equipped with a grease adding pipeline, and various liquids can be added in an appropriate amount.

5. The machine has compact structure, beautiful appearance and small footprint

6. The double-shaft paddle dry powder mixer is not allowed to start with full load, and the loading capacity is strictly controlled within 0.4-0.6. If the material is too heavy, it is best to feed the material while the machine is running.

| Model | Volume (m³) | One-time mixing (kg) | Motor power (kw) | Weight (kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Introduction Liter mixer is a kind of equipment used for mixing various materials, widely used in che...

Introduction The food additive mixer is a kind of equipment widely used in the food industry, mainly ...

Introduction Vertical screw mixer is a common powder mixing equipment, widely used in chemical indust...

China,Yanjin county forest park gate to the west 1000 meters north road.