Rotary drum feed mixer is a type of equipment commonly used in feed production. It mixes feed raw materials of different types and specifications through the rotation of the drum.

Rotary drum feed mixer is a kind of equipment commonly used in livestock feed production, which is used to mix different types and proportions of feed raw materials to form a uniform feed mixture. The following will introduce the working principle, advantages, functions and application scenarios of the rotary drum feed mixer.

Rotary drum feed mixer is a piece of equipment commonly used in agricultural and animal husbandry production, with a wide range of customer application scenarios. Rotary drum feed mixers play an important role in farms. Farms need to mix different types of feed to ensure that animals receive balanced nutrition. This equipment can efficiently mix powdered, granular or liquid feed ingredients to ensure the even distribution of various nutrients in the feed, improve the quality of the feed, and thereby promote the growth and health of animals.

Rotary drum feed mixers are also widely used in feed processing plants. Feed processing plants need to mix various raw materials to produce feed products that meet market demand. The drum feed mixer has a large capacity and efficient mixing capacity, and can quickly and evenly mix feed ingredients of different ingredients to ensure product quality and consistency. In addition, the equipment can also be automatically controlled according to customer needs, improving production efficiency and reducing labor costs.

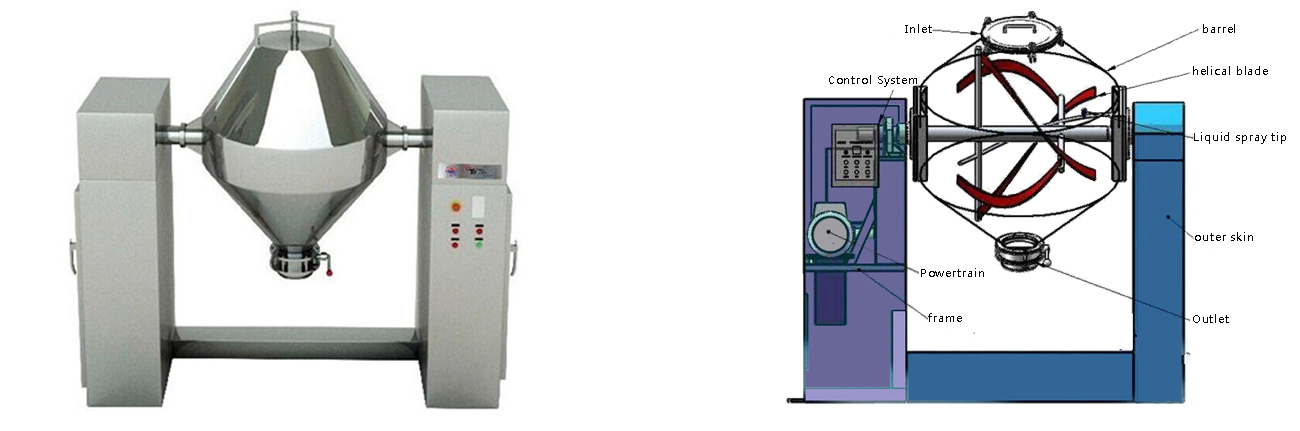

The working principle of the rotary drum feed mixer is to make the feed raw materials roll, tumble, impact and mix continuously in the drum by rotating the drum. The continuous movement of the feed materials in the drum enables various materials to contact and mix with each other, so as to achieve the effect of uniform mixing. At the same time, the rotary drum feed mixer also sets the appropriate mixing time and rotation speed according to the needs to ensure a good mixing effect.

1. Simple and compact structure, easy operation and maintenance. The equipment has a simple structure, consisting of a motor, a drum and a transmission system, and is easy to operate and maintain.

2. The mixing effect is good and the feed is uniform. Due to the characteristics of the internal movement of the drum, the feed ingredients can be fully contacted and mixed to ensure the uniformity of the feed composition.

3. Ability to adapt to different scales and needs. Rotary drum feed mixers are available in models of different sizes and capacities, suitable for feed production of different scales and needs.

4. Save time and cost. Rotary drum feed mixer has high mixing efficiency, which can greatly shorten the mixing time and save labor and energy costs.

1. Evenly mix feed ingredients of different types and proportions to ensure the balance of feed ingredients.

2. Improve feed utilization and reduce feed waste. Through mixing, the various ingredients in the feed will be better utilized and waste will be reduced.

3. Improve feed taste and digestion and absorption effect. The mixed feed tastes better, is easy for livestock and poultry to eat, and helps to improve the effect of digestion and absorption.

4. Reduce production cost and improve production efficiency. Reasonable mixing of feed materials can reduce the amount of feed and milling time, reduce production costs, and improve production efficiency.

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

China,Yanjin county forest park gate to the west 1000 meters north road.