Screw conveyor below collection hopper

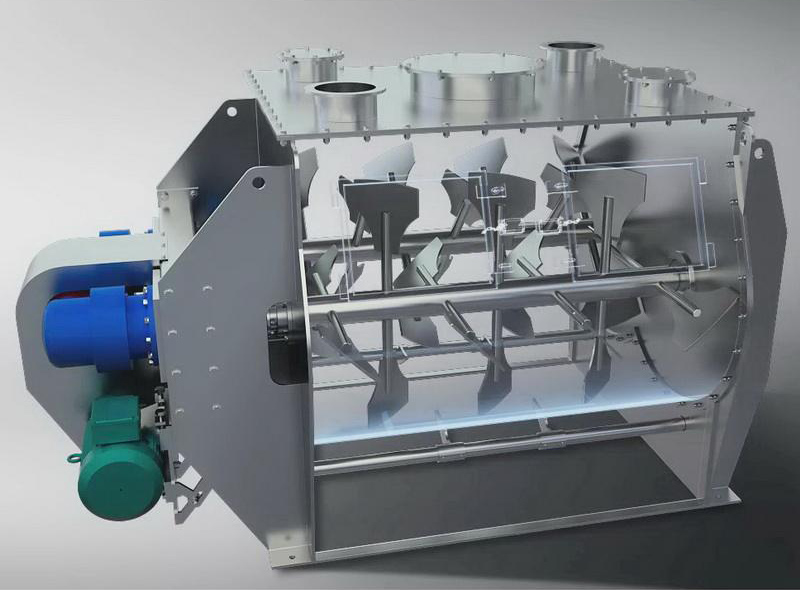

Stainless steel paddle mixer is made of food-grade 304 stainless steel. The barrel is equipped with two paddles that rotate in opposite directions. The strong reverse speed can shorten the mixing time, and the critical parabolic speed can make the materials evenly mixed. It is suitable for food, chemical industry, medicine, etc. The powder, flake, block, small particles or relatively viscous materials in the industry have the advantages of cleanliness, corrosion resistance and wear resistance.

Stainless steel paddle mixer is mainly used to fully mix powder, flake, block, small particles or relatively viscous materials. It is mainly used in various feed factories to fully mix the corresponding materials according to the type of feed.

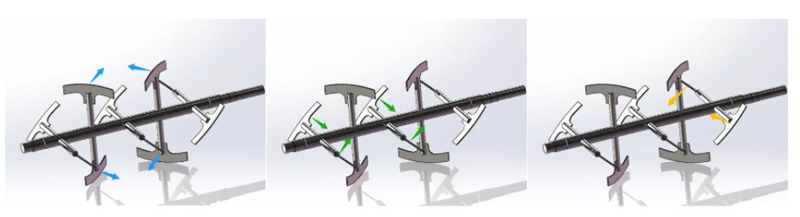

The two rotors inside the stainless steel paddle mixer with opposite rotation directions have multiple blades. When the material enters the machine, the blades drive the material to move. During the movement, the material will move according to the direction of the two rotors. Here, sufficient mixing can take place quickly.

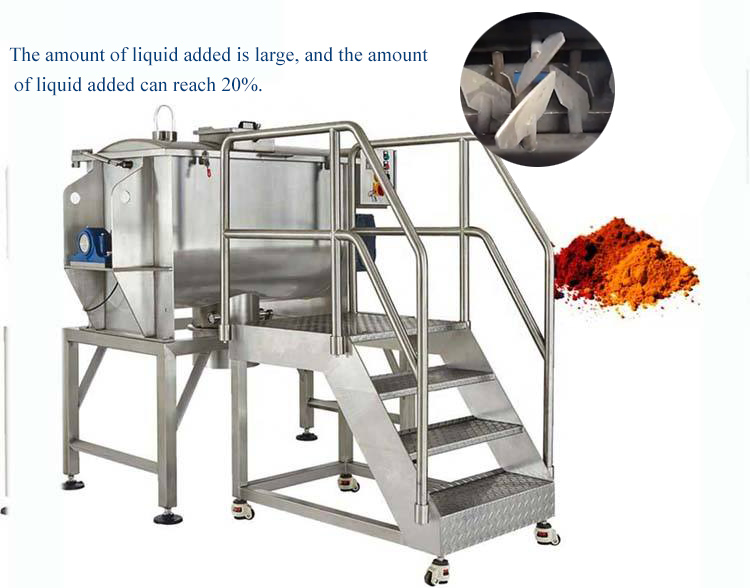

1. Made of SUS304 stainless steel, it will not pollute the mixed materials, and meets the hygiene standards of food and medicine.

2. Low mixing speed, soft, stable operation, no separation phenomenon; high uniformity (CV≤3-5%), short mixing time (3-5 minutes), and fast discharging.

3. The machine slot is a unique "W"-shaped structure, with a small opening, a large middle and a narrow lower part to reduce residues.

4. The effective mixing volume is increased, the variable range of the filling coefficient is large, and the effective volume and filling amount are increased by 40% compared with similar models.

5. The amount of liquid added is large, and the amount of liquid added can reach 20%.

6. In materials with large physical differences such as specific gravity, particle size and shape, it is not easy to produce segregation during the mixing process.

| Model | Volume (m³) | One-time mixing (kg) | Motor power (kw) | Weight (kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing

Horizontal dry powder mixing machine ribbon mixer equipment batch blending for food packing can effic...

Horizontal Spice Blender Mixer Machine Dry Food Ribbon Powder Mixer

In the food processing industry, how to achieve efficient mixing of dry foods has always been a key i...

stainless steel horizontal industrial ribbon mixer dry powder mixing machine

Stainless steel horizontal industrial ribbon mixer dry powder mixing machine is a kind of equipment u...

Horizontal Ribbon Blender for Making Powder Coatings

Horizontal ribbon blender for making powder coatings is ideal for efficient and even mixing of powder...

Horizontal Double Ribbon Mixer Machine for Dry Powder Mixing

In modern industrial production, powder mixing is a key process link. The horizontal twin screw belt ...

Paddle mixer is mainly used for all kinds of dry-mixed mortar and high-grade putty powder that requires high mixing unifo ...

Gravityless twin shaft paddle mixer, also called gravityless mixer, is used to mix powder materials such as dry powder mo ...

Animal feed paddle mixer is used for grain powder mixing in feed pellet production line, the mixing time is 3-5 minutes, ...

China,Yanjin county forest park gate to the west 1000 meters north road.